WHAT IS OBD-II?

Integrated diagnostic systems are present in most cars and trucks

today. During the 1970s and early 1980s, manufacturers began using electronic

means to monitor functions and diagnose engine problems. This was primarily to

meet EPA emissions standards. Over the years diagnostic systems have become

more sophisticated. The most recent standard is OBD-II, this standard was

introduced in the mid 90s, it controls the engine almost completely and also

monitors parts of the chassis, body, accessories and the car's control

diagnostic network.

SOME OBDII HISTORY

To combat the pollution problem in the Los Angeles basin, the state

of California required emissions control systems on automobiles of the 1966

model year. The Federal Government extended these controls nationwide in 1968.

The US Congress passed the Clean Air Act in 1970 and established

the Environmental Protection Agency (EPA). This began the publication of a

series of emissions standards and requirements for vehicle maintenance. To meet

these standards, vehicle manufacturers created electronic fuel supply and

ignition systems where sensors measure engine performance and adjust the

systems to reduce pollution. These sensors also began to be used to diagnose

the vehicle.

At the beginning there were few standards and each manufacturer had

its own systems and signals. In 1988, the Society of Automotive Engineers (SAE)

established a standard connector and set of diagnostic test signals. EPA

adapted most of the standards from SAE's diagnostic programs and

recommendations. OBD-II is an expanded set of standards and practices developed

by SAE and approved by the EPA and CARB (California Air Resources Board) for

implementation on January 1, 1996.

THE NEED FOR OBDII

The Environmental Protection Agency is

responsible for reducing "mobile emissions" from cars and trucks and

has the power to require manufacturers to build cars that meet increasingly

stringent emissions standards. Furthermore, manufacturers must maintain

automobile emission standards for the life of the vehicle. OBD-II provides a

universal inspection and diagnostic method to ensure that the car is working

within the manufacturer's specifications. While there is an argument as to the

exact standards and methodology used, the fact is that there is a need to

reduce the level of pollution, caused by vehicle emissions, in our cities, and

we have to live with these requirements.

OBD-II PROTOCOLS

There are three basic OBD-II protocols in

use, each with minor variations in the communication pattern between the

on-board diagnostic equipment and the scanner. Although there have been some

manufacturer changes between protocols in recent years, as a general rule,

Chrysler vehicles, European and Asian vehicles use the ISO 9141 protocol. GM

vehicles use the SAE J1850 VPW (variable pulse width modulation) protocol. and

Ford vehicles use SAE J1850 PWM (Pulse Width Modulation) communication

patterns.

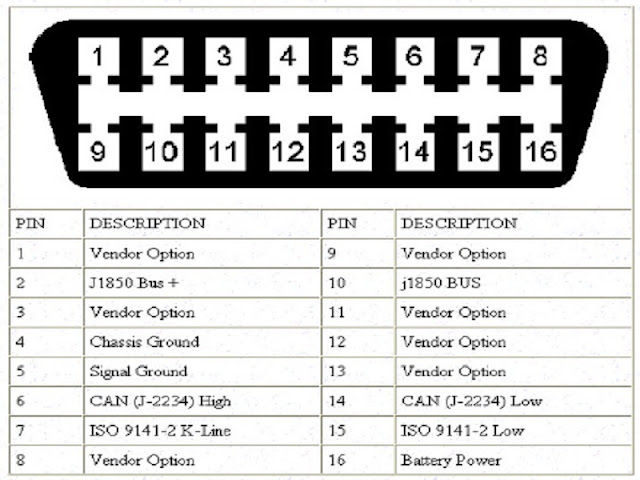

You can also tell what protocol a car

uses by examining the connector. If the connector has a pin in position #7 and

no pin in position #2 or #10, then the car has the ISO 9141 protocol. If no pin

is present in position #7, the car uses an SAE protocol. . If there are pins in

positions #7, #2 and #10, the car can use the ISO protocol.

While there are three OBD-II electrical

connection protocols, the command set is set according to the SAE J1979

standard.

HOW DO YOU MEASURE OBD-II OUTPUT?

Pre-OBD-II cars had multiple connectors

in various locations under the dash and under the hood. All OBD-II cars have a

connector that is located in the cabin easily accessible from the driver's

seat, so that a scanner can be connected with a cable

The “Check Engine” light or MIL

The Check Engine light or MIL. It has

three types of signals

Occasional flashes show a temporary malfunction.

Permanently on if the problem is more

serious.

Constant flashing if the problem is very

serious and can cause serious damage if the engine is not turned off

immediately.

In all cases, a reading is taken from all

the sensors and stored in the vehicle's central computer.

If the fault signal is caused by a

serious problem, the MIL light will be on until the problem is resolved and the

MIL light is reset.

Intermittent faults turn on the MIL

momentarily and turn off before the problem is located. The reading from the

sensors at the time of the failure, which is stored in the computer, can be of

high value in diagnosing these problems. However, if the vehicle completes

three driving cycles without the problem reappearing, the reading is cleared.

FAULT CODE (DTC)

Fault codes are regulated by the SAE

J1979 standard and is the standard used by vehicle manufacturers today. Fault

codes consist of 5 characters, which are a letter followed by four numbers.

The first character, which is a letter,

indicates the function of the vehicle according to the following.

P - Powertrain or engine and transmission

(Powertrain)

B - Body

C - Chassis

U - Undefined

The second character indicates whether

the code is generic, defined by SAE, or specific, defined by the vehicle manufacturer.

0 – Generic for all brands and defined by

SAE.

1 – Specific defined by the vehicle

manufacturer, the code is generally different for each manufacturer.

Codes 0001 to 0999 are completely defined

by SAE. Codes from 1000 to 1999 are defined by the manufacturer and only follow

the SAE standard in format.

The third character indicates the vehicle

subsystem.

0 - The complete electronic system

1 and 2 - Combustion control

3 - Ignition system

4 - Auxiliary emission control

5 - Speed and idle control

6- ECU and inputs and outputs

7 - Transmission

The fourth and fifth characters indicate

the fault.

The following image represents what we

have described.

OBDII ERROR CODE READER

OBD2 error code readers began to be one

of the first tools that car owners began to use in recent years to diagnose

problems related to engine and transmission management due to the simplicity of

their operation, generating for the which uses important failure data.

The popularity of these code readers has

increased in recent years, having the same diagnostic connector, along with

connection protocols already pre-established in all cars to connect with the

engine computer, regardless of the brand or style. of these readers an almost

pocket-sized basic tool due to its small size.

We could never compare a code reader like

these with the famous scanners that most mechanics have, since these scanners

are more powerful tools in exploring all the control units or modules that work

in the car.

In this way, these code readers, for the

most part, limit themselves to informing us why the service engine soon or

check engine light is on (both mean the same thing), extracting the error code

that has been generated and also having the possibility of delete it, however

in almost all cases this information will only refer to the engine and

transmission.

Some code readers, in addition to

extracting and erasing the code, also allow you to see in real time the

operation of some engine sensors (not all) in addition to having frozen data

that gives us an idea of what condition the engine was in when the problem was

generated. Error code.

There are also these Bluetooth tools so

that a small interface connects to the diagnostic connector and with software

either on a computer or even on a smartphone we will have access to all this

information, making it so that even with our cell phone we can obtain a

diagnosis that indicate why the yellow check engine light stays on, some of

these applications allow you to create custom clocks for speed, rpm, engine temperature,

average consumption and much more.

FUNCTIONS OF A CODE READER.

Extract the error code.

Provide frozen data

Reading data in real time from some

sensors

Code erasing

Most are limited to engine and

transmission.

THEY WILL NOT BE ABLE TO ACCESS MOST CODES

ABS brakes

Airbags

Keys

Traction control

Electric steering

Air conditioning