Block

cell is the adaptive strategy of the PCM. It’s the PCM’s ability to learn and to

correct for fuel imbalances. During a rich mixture problem, the PCM will have

lowered the LTFT to correct the problem. If it is successful then this

information would be saved in the block cell memory of the ECM.

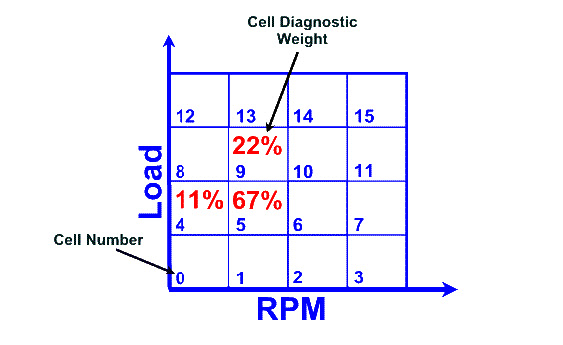

There are

15 cells that it could place this information in. Each cell represents a

specific load and rpm range. Whatever cell it had to make the correction in

would now represent the LTFT that was able to get the mixture right.

When the

battery is disconnected then this memory is erased and it has to relearn

itself. All cells will start off at 0

when the memory is erased. These cells would change as the car is driven to

reflect the adjustment the long term fuel trim had to make to keep the short

term fuel trim averaging 0.

Each cell

represents rpm and load. With 15 cells every rpm and load will be represented

in block cell starting from idle to WOT. You can use the block cell to look for

rich or lean conditions that only occur under specific rpm or load ranges. If

you see a cell with a very high or low number than there is a problem in that

area. Now think of the components that could only affect the mixture in that

area. You may be able to better pin point the problem.

Note:

after repairing a problem make sure to clear the block cell memory. Remember,

it will still be in the corrected mode after a repair unless the memory is

cleared.

Fuel Trim How to Diagnose Using Trim I

Finding

vacuum leaks is easy using STFT. Simply start the car, let it go into a closed

loop, monitor the O2 sensor voltage and the short term fuel trim, then use

propane and run it around possible vacuum leak areas. If O2 sensor voltage goes

up and the STFT goes to a negative, you have found a vacuum leak.

NOTE:

always be careful when working with propane.

Let’s

say that there is a severe rich condition. One the computer can’t control. The

PCM will try to lean out the mixture, which will be evident with a high

negative STFT and LTFT. At this point, the PCM will realize that it cannot

repair the problem and turn on the MIL code for rich running. Before the PCM

sets the code, it will look at all the contributing circuits/ sensors and

determine if they are okay. If so, it will set the rich condition code. If one

of the sensors was found to be outside of operating range, it would set the

sensor code, then a rich code. The same is true for a lean condition.

Remember

if we had a bad load sensor such as a MAF, and it is generating a signal

voltage to high load of the engine, it might move into the wrong block cell.

This in turn would create a wider pulse width causing it to fail a loaded mode

smog test.

Fuel Trim How to Diagnose Using Trim II

Fuel

trim can be a great diagnostic tool. It can help you narrow down the problem.

Be careful when looking at STFT. If the PCM was able to correct the fuel

mixture with the LTFT, then the STFT will be normal around 0. Even if the STFT

is normal, it doesn’t mean there isn't a problem with the fuel metering system.

A high negative or high positive LTFT will be the indication that there is a

problem with the fuel metering system, but the problem is controllable. When I

say it’s controllable, that means the problem isn't out of the computer’s

ability to correct. If the problem falls outside of the computer’s ability to

correct, it will set a code and fall into open loop. When in open loop we

cannot use the fuel to diagnose.

Let’s

say you have a rich running problem that the computer can control. The STFT

will be normal around O, but the LTFT should be a negative number. If you see

this condition you can determine the PCM is ok, and the O2 sensor is sending

the right signal. Since this is not a major problem, look for parts of the fuel

system that the PCM can’t control like leaking injectors, canister purge, fuel

in the crankcase, and high fuel pressure. Sensors are also on the list of items

to check. If a sensor is sending a slightly higher signal than it should, the

PCM would see this as a rich command. This would cause the PCM to widen the

injector pulse width to force a rich command. The O2 sensor would see the rich

mixture and send a high voltage signal to the PCM. The PCM would see this as a

rich mixture and respond by leaning it out with a negative fuel trim. It will

not set a code for the sensor because it’s still within the sensor limits. MAF

sensors commonly cause high negative or high positive fuel trim numbers.

NOTE:

if you get the proper response by the PCM to a particular problem of rich or

lean, then you can safely say the PCM and O2 are good. The response should

always be opposite of the problem. If you have a rich condition followed by a

rich command of high positive fuel trim then look to the O2 sensor as the

problem. Remember fuel trim only corrects from the O2 sensor signal. Let’s say

you have a lean condition, the PCM can control the STFT to be normal around

0.The LTFT will be positive adding fuel to correct for the problem. Areas of

concern would be a small vacuum leak, resurrected injectors, low fuel pressure

or possibly a sensor out of calibration sending a lean signal.

Fuel Trim

Graphical Representation of Fuel Trim